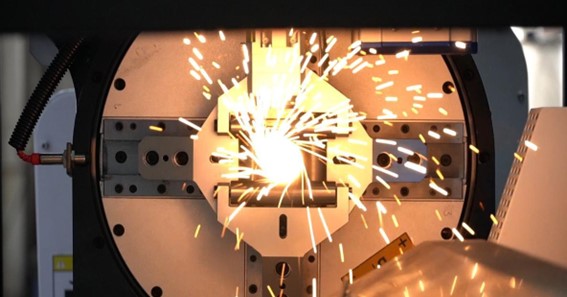

Introduction: Understanding Tube Laser Cutting Machines

Tube laser cutting machines are gaining popularity in many industries due to their accuracy, speed, and versatility. These machines use laser beams to cut through various materials, including steel, aluminum, and copper. A tube laser cutter can operate on different shapes and sizes of tubes, making it a flexible machine that can fulfill various manufacturing requirements. Although tube laser cutting machines can be a significant investment, their advantages make them a worthwhile investment in the long term. In this guide, we will highlight the critical considerations when choosing a tube laser cutting machine.

Key Considerations: Budget and Cutting Capabilities

One of the critical considerations when deciding on a tube laser cutting machine is your budget. The cost of tube laser cutting machines can vary widely based on features such as power, automation, size, and capacity. However, even the simplest models can be expensive, so it’s essential to have a clear budget before making a purchase. Another vital consideration is the cutting capabilities of a machine. Different machines can cut different types of materials, thicknesses, and geometry. It’s crucial to determine the specific cutting requirements of your industry to choose a machine that can meet your needs.

Click here – What to Consider When Choosing a THC Syrup Product

Types of Tube Laser Cutting Machines: Fiber vs. CO2

There are two main types of tube laser cutting machines: fiber and CO2. A fiber tube laser cutting machine uses fiber optic cables to deliver a laser beam to the cutting head, while a CO2 tube laser generates the laser beam through a gas mixture. Fiber lasers are known for their high cutting speeds, lower maintenance costs, and energy efficiency. CO2 laser cutters offer superior cutting quality with a wider range of materials. It’s vital to understand the differences between these two technologies to choose the one that suits your requirements best.

Power and Precision: Evaluating Cutting Speed and Accuracy

Cutting speed and accuracy are critical factors that you must evaluate when selecting a tube laser cutting machine. The cutting speed of a machine depends on the laser power, with higher power lasers being faster. Higher precision cutting requires a machine that can maintain stability and precision during the cutting process. Laser beam quality and focusing are also important factors that determine accuracy. You should evaluate a machine’s speed and precision carefully to determine if it can handle the cutting needs of your industry.

Automation Features: Enhancing Workflow Efficiency

Automation features such as loading and unloading systems, material handling, and software integration can significantly improve the efficiency of a tube laser cutting machine. Automated loading and unloading systems can significantly reduce material handling time, while software integration improves the accuracy and speed of cutting programs. Choosing a machine with high levels of automation can maximize workflow efficiency and reduce labor costs.

Size and Capacity: Choosing the Right Machine for Your Needs

When choosing a tube laser cutting machine, it’s crucial to consider size and capacity requirements. The cutting length and diameter of the machine should match the size of the tubes you need to cut. Choose a machine with a larger capacity than required, as this can save you money in the long run by future-proofing your manufacturing operations.

Maintenance and Service: Ensuring Longevity and Performance

Maintenance and service are essential to keep your tube laser cutting machine running smoothly and efficiently. Regular maintenance, including cleaning, inspection, and calibration, can ensure that your machine achieves optimal performance and longevity. Choose a manufacturer that offers excellent customer service and technical support to address any issues that may arise.

Click here – The History of Volkswagen

Conclusion: Making an Informed Decision for Your Business

Choosing the right tube laser cutting machine is critical to achieving optimal manufacturing efficiency and quality. The decision requires careful consideration of factors such as budget, cutting capabilities, power, precision, automation features, size, and maintenance. By taking the time to evaluate the alternatives, you can make an informed decision that minimizes your costs, maximizes your productivity, and ensures the longevity and optimal performance of your machine.